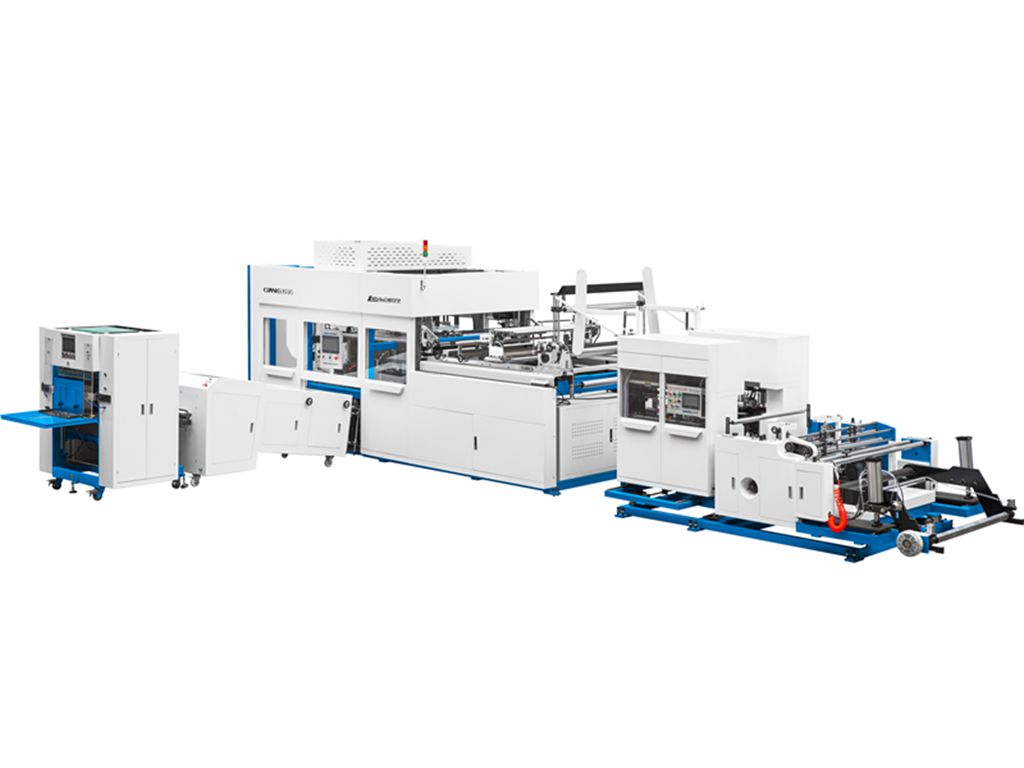

Product Application

Leader-15 One Time Forming Non Woven Box Bag Making Machine is suitable for Laminated PP non woven fabric, Non-laminated PP non woven fabric, Aluminum film non woven fabric, Glitter film non woven fabric, Laser film non woven fabric,etc. It using non woven fabric roller to produce non woven box bag aromatically.

|

Main Technical Variables |

||

|

Type |

LEADER-15 |

|

|

Bag Capacity |

80-100 pcs/min |

Speed depends on bag size |

|

Bag Length |

180-500 mm |

|

|

Bag Height |

180-450 mm |

There is a one-to-one mapping between Bag Height and Bag Gusset |

|

Bag Gusset |

80-200 mm |

|

|

Power Supply |

Power Supply |

|

|

Total Power |

38KW |

|

|

Machine Size |

8500X6600X2600MM |

|

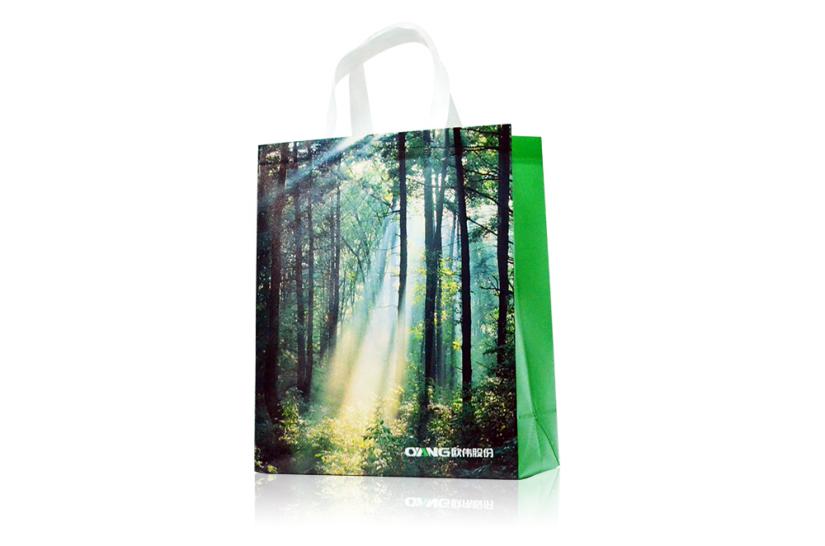

Bag Type - Leader can make

Non woven box bag

Lamination film thickness: 0.2 to 0.24 cm,

Non woven thickness: 90 grams per square meter ,

less than general weight cotton sails tarpaulins1/10 ,

but its vertical and horizontal tensile strength up to 30 kg can be reached.

Long-term use in infrared, ultraviolet , laser and acid rain, snow or frost, ecological or other physical and chemical environment.

PP non woven box bag

Non woven thickness: 90-120 grams per square meter.

Choosing traditional printing machine printing the non woven

fabric roll by roll before bag making.

Aluminum film non woven box bag

Composite materials

1. Plastic film coated with a thin layer of aluminum

2. non woven fabric

In a high vacuum state by high temperature the aluminum melt

evaporated and the vapor deposition of aluminum accumulated

on the surface of the plastic film so that the plastic film surface

with a metallic luster .

Glitter film non woven box bag

Composite materials

1. Glitter film with printing outside

2. non woven fabric

Glitter film suitable for offset printing, gravure printing ,

screen printing, special printing, stamping and other

processing methods.

It has been widely used in all walks of life on the packaging

industry decoration market

Embossing non woven bag

Composite materials:

1. One layer of BOPP Film, One layer of Non woven fabric

2. Double layer of non woven fabric

Processing way:

1. Hot stamping BOPP film

2. Laminated BOPP film with Non woven fabric

3. Embossing the laminated material.

4. Using Ounuo Leader to make the bag

PP woven bag

Composite materials:

1. One Layer of BOPP film, One layer of Woven fabric

Processing way:

1. Rotogravure printing BOPP film inside

2. Laminated BOPP film with Woven fabric

3. Using Allwell Leader to make the bag

- Packing project conserlor

- Contact Name: Emy Tung

- E-mail: inquiry@allwell-group.com

- Mobile Phone: +8613567711278

- WeChat: 13567711278

- WhatsApp: +8613567711278